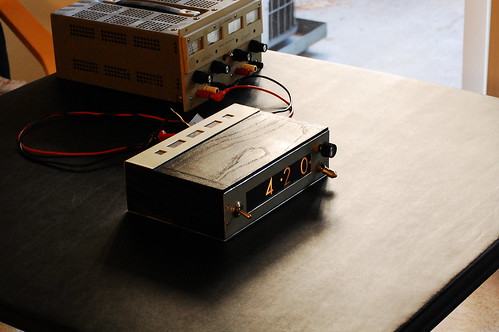

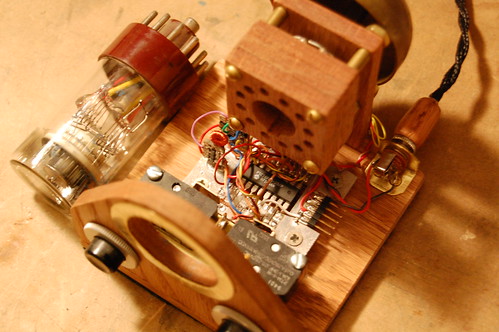

One of my CRT clocks has a small joystick on the front which is used to set the time. I built it a while ago using an idler wheel from an old VCR.

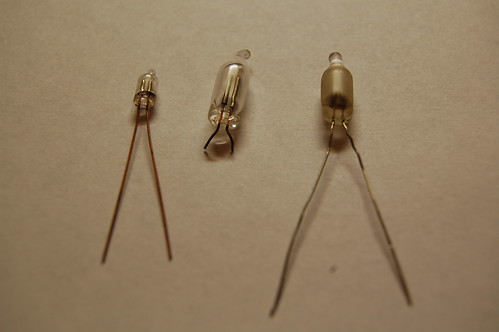

Well, the other day I found another idler wheel from the same VCR, and I decided to share the construction technique so that you can make one too. It’s pretty simple and takes an hour or two. You will need a VCR idler wheel that looks like the one in the picture below, four microswitches (you can scavenge these from an old computer mouse), a spring, and a piece of sheet steel to mount the whole arrangement on. The sheet metal must be steel for reasons I will discuss later.

First, take apart the idler wheel by gripping the top washer with a pair of vise-grips, taking care not too dent it too much. Grab the metal shaft with another pair of pliers and pull the assembly apart. Slide off the screw thread and the metal washer, and take the top washer (which has a convex side and a flat side), and slide it back on to the metal shaft about halfway.

Drill a hole in the sheet metal, and make the hole somewhat larger than the shaft. For my joystick I used a 3/32″ diameter drill. Insert the metal shaft into the hole so that the convex part of the washer faces down against the sheet metal. Turn the piece of sheet metal over and drop a spring over the shaft, then press the remaining metal washer onto the shaft so it captures the spring and tensions it slightly. If you’ve done things correctly, when you push the shaft to the side, it will spring back to the middle. You may need to adjust the spring tension if the shaft doesn’t return all the way. If the shaft can’t move very much in any direction, you’ll need to enlarge the hole.

In the previous picture, you can see how the convex side of the washer allows the joystick to “roll” against the surface of the sheet metal. When you let go of the shaft, the spring tension pushes the shaft back to the center. The joystick action puts a lot of wear on the sheet metal which is why it’s important to use steel instead of a softer metal like brass or aluminum.

Now it’s time to begin mounting the switches to the sheet metal. You may want to lay them out by hand first just to make sure there is room for them all, and that the actuators end up in the right position. Skip ahead a few photos to see how I arranged my switches.

Position the switch so that the washer on the reverse side of the sheet metal will hit the actuator just right. You don’t want the washer pushing in too hard–the hole in the sheet metal should stop the shaft from moving to the side rather than the actuator in the switch itself. At this point you may need to adjust the bottom washer so that it lines up with the switch actuator. In my joystick, I had to use a different spring to get the correct tension when the bottom washer was lined up correctly.

When you are finished lining it up, mark the sheet metal where the hole should go (I just dropped a drill bit in the switch’s mounting hole and twirled it between my thumb and forefinger, holding the switch down with my other hand). After you drill the first hole, put a small machine screw into the hole and secure it with a nut on the other side. You can rotate the switch to fine tune its position so the washer hits it in the right place. When it’s dialed in, mark and drill the next hole.

In this photo most of the switches are mounted, and you can see that I’ve drilled one mounting hole for the last switch.

Once the last switch is mounted, take a look at the following photo and make sure that your washer hits every switch actuator correctly.

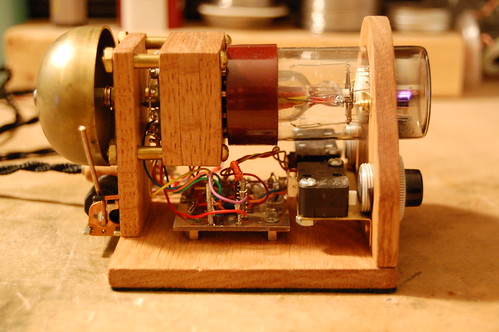

At this point I drilled some mounting holes in the corners and took the whole thing apart, and cut the mounting plate out of the larger piece of sheet steel. It’s easier to work with a larger piece of sheet metal when drilling holes and such rather than a tiny piece that is harder to clamp. After putting everything back together, the joystick now looks like this:

The joystick is finished, and it’s ready to be mounted in a front panel. For this joystick, I’ll probably mount it behind a 1/4″ thick piece of oak, so I will drill a big round hole for the joystick shaft and then use wood screws to mount the metal plate to the back of the wood. To dress up the front, I could use a piece of brass pierced with a plus-sign-shaped cutout to cover the hole in the wood like I did on my CRT clock in the first picture. As a finishing touch, I will mount a small wooden knob or perhaps a brass bead on the end of the joystick shaft.